09 August 2023

Executive summary

There was a time, not too long ago, when the overwhelming perception of the data centre was that every facility was unique.

The snowflake phase of data centre design coincided with the height of the enterprise data centre era, when virtually every company felt the need to own and operate its own facility. That may seem like a lifetime ago, but this remained the norm until the cloud matured and the gradual bifurcation of the data centre space produced the hyperscale and edge-dominated landscape we know today.

Of course, the enterprise data centre is far from extinct. Hyperscale and edge are growing at faster rates, but the pressures driving change across the enterprise segment — the desire to streamline and simplify operations and reduce costs and carbon footprint — also are spurring changes in data centre solutions and design. The purpose-built enterprise data centre is fading from view, replaced instead with standardized designs featuring prefabricated, modular buildings and components.

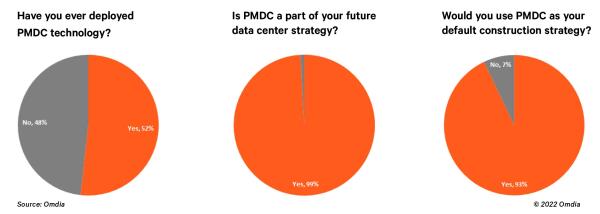

In fact, the widespread acceptance of prefabricated modular data centre (PMDC) solutions may be outpacing the more publicized shift to hyperscale and edge. In a recent Omdia survey of 228 companies that operate their own data centre, just over half reported having deployed PMDC approaches in their data centre already, and a stunning 99% said PMDC would be a part of their future data centre strategy.

The snowflakes are well and thoroughly melted. This white paper will highlight why PMDC options have become so widely adopted even among hyperscale data centre operators.

The case for prefabricated design

The increased popularity of modular data centre design is not surprising. Consider: by moving construction and integration off site, those tasks can be performed under tightly controlled factory conditions by trained specialists. This can happen while on-site preparation continues, compressing construction timelines. Reducing the time on a project reduces the cost of that project and improves overall total cost of ownership (TCO) by shortening the time to revenue. Factory integration also tends to reduce service issues and costs. Bottom line: the TCO of a PMDC deployment can be significantly less than a traditional stick build.

For some, there is a stubborn, lingering misperception of prefabricated data centre modules as shipping containers housing IT infrastructure and racks, which isn’t state of the art. In fact, 451 Research said “the perception that ‘prefabricated modular = container’ is probably the most crucial misunderstanding of them all.”

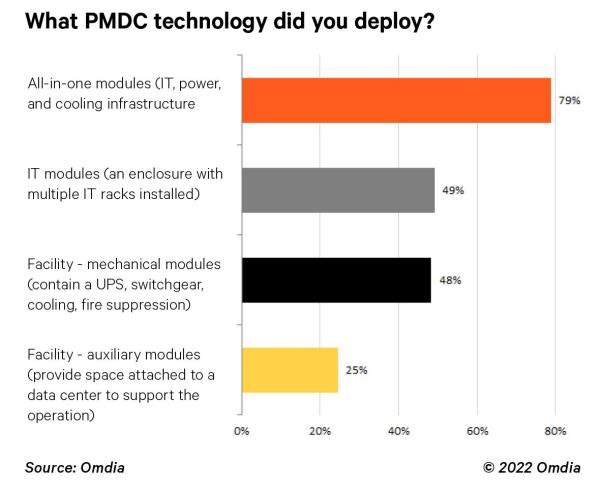

Modern prefabricated modules are sleek, fully integrated, efficient building blocks. They are increasingly common choices for new data centres or additions to existing facilities. In fact, according to the Omdia research, 79% of those who have deployed some type of prefabricated solution said they had deployed this type of all-in-one module.

Maybe your mind’s eye is more conservative, picturing smaller prefabricated components — integrated racks, rows, or aisles built in the factory and deployed with servers and infrastructure included. These are popular choices when an organization needs to add capacity incrementally, often within an existing building.

Increasingly, however, another iteration of prefabricated design is shaping the data centre. This hybrid concept relies on facility infrastructure modules — most commonly power modules, but cooling, IT, and mechanical modules offer similar benefits. In these cases, a holistic system — power, for example (including batteries) — is integrated and tested off site and deployed ready for immediate installation. These modules can be configured in an enclosed unit or mounted on an open skid.

The elephants in the room

We can’t discuss hybrid design without addressing the one universally accepted truism about today’s data centres. It goes something like this: Sure, enterprise data centres are becoming more standardized, but hyperscale data centres drive design innovation today, and they do not order off the shelf.

This is the mainstream perception of the hyperscale market, and historically that thinking has been accurate. But what if I told you this sentiment is false?

In actuality, today’s hyperscale data centre operators are increasingly embracing the benefits of standardized design. To be clear, these are not cookie cutter data centres by any stretch, but as these operators race to add capacity to existing facilities or build new data centres, they are more open to standardized design features than ever before. In fact, we would estimate 70-80% of Vertiv hyperscale customers are using a hybrid design in their facilities.

In much of Europe, Middle East, Africa, Asia, and Australia, especially, some of the leading cloud providers are turning to colocation providers (colos) to meet increasing demand. These regional colos have a comprehensive understanding of specific building requirements and codes and are better equipped to advance a project quickly than Silicon Valley-based cloud providers. So the cloud provider enlists the colo to build and operate the data centre, and colos have a much higher comfort level with standardization and understand the benefits of repeatability in rolling out these facilities.

As the hyperscale community — a relatively small group, despite the size of their data enters — sees these advantages play out, they are increasingly accepting and even seeking out ways to reduce their deployment timelines and costs through standardized, often prefabricated, designs and components. More and more, conversations with hyperscale customers start with, “What’s your standard design?” From there, the modules can be configured to the specifications of a given customer, and that design can be repeated across deployments.

Make no mistake, hyperscale data centres remain the snowflakes of the data centre ecosystem. But those snowflakes are starting to share some features.

Exploring the hybrid approach

There are several advantages to a hybrid design. These modules and skids can be installed in new builds or in retrofits of existing data centres. They deliver the customary benefits that come with other PMDC design approaches — reduced deployment timelines and repeatable, reliable construction with fewer service calls. Additionally, depending on the architecture, they can reduce the physical footprint of the systems they replace by as much as 30%, creating additional white space for revenue-generating equipment.

There is another important distinction with power modules. In most cases, because they are fully integrated prefabricated systems, they are considered equipment rather than part of the building. This simplifies compliance with building codes, standards and regulations. Traditional installations are subject to those codes.

Finally, the modules can be designed to optimize performance in ways traditional systems simply can’t. For example, power modules are an electrical component, but they can be designed with enhanced thermal properties — using aisle containment principles, for example. This type of optimization improves the overall thermal profile of the facility and reduces energy use and costs associated to cooling. Cooling skids are custom designed to provide additional capacity to an existing site or to upgrade cooling in an entire facility to support increased capacity and improved efficiency.

The choice of module or skid depends on the needs of a specific site, but as a broad recommendation, power module-based design is most appropriate for data centres up to two stories, and skid-mounted solutions are better suited for any building higher than that.

Hybrid design in practice

Vertiv worked with a customer in the Middle East to design and build a Tier III data centre with a 10.8 megawatt (MW) IT load, housing 1,350 racks with potential for 25% expansion in the future. The expected timeline for design, construction, commissioning, and Uptime Institute Tier III certification was 18 months, with three separate project locations running in parallel.

Leaning on prior experience designing and building hyperscale data centres, Vertiv recommended a hybrid design with components of four types of critical systems prefabricated off site, while the ground works were under way and the building shell erected.

Vertiv recommended more than 100 pieces of prefabricated modular equipment, including power modules, battery modules, cooling skids (with perimeter computer room air handler units and concurrently maintainable chilled water piping) and IT modules.

Prior to placing the order, the Vertiv Integrated Modular Solutions (IMS) Engineering team developed the conceptlevel design, and the customer made a reference visit to another hyperscale site with Vertiv hybrid components. This is how the project unfolded:

- April 2018 Design and build project awarded; started design process

- July 2018 All design documentation submitted for review

- October 2018 Factory Acceptance Test (FAT) of first batch of prefabricated modular items

- December 2018 On-site delivery of prefabricated modular components allowing fit out for 6 MW of IT load

- February 2019 Final Vertiv installation

- April 2019 All inspections complete and facility goes online

Vertiv and their authorized local partner completed the design and construction work in 10 months, and the first facility was fully operational within a year.

Conclusion

The evolving demands of data centre operators and the broader data centre market are changing long-held perceptions of facility design. Prefabricated modular design already is the dominant trend among enterprise data centres, and the same drivers — speed, cost and reliability — are pushing hyperscale operators to dip their toes in the PMDC waters. The emerging preference among the hyperscale segment is a hybrid design leveraging facility infrastructure modules or skids, which are full systems, integrated and tested off site and ready for installation when deployed.

The hybrid approach can reduce footprint by 30% over a traditionally constructed building and radically shorten construction timelines — potentially by as much as half. This repeatable approach can also increase facility energy efficiency, eliminate the need for lengthy building code inspections, and improve system reliability through factory construction and testing. The benefits have motivated both enterprise data centre operators and hyperscalers to embrace standardization broadly and hybrid designs more specifically.

As a result, the days of the snowflake data centre are dwindling with data centre owners and operators reaping the rewards.